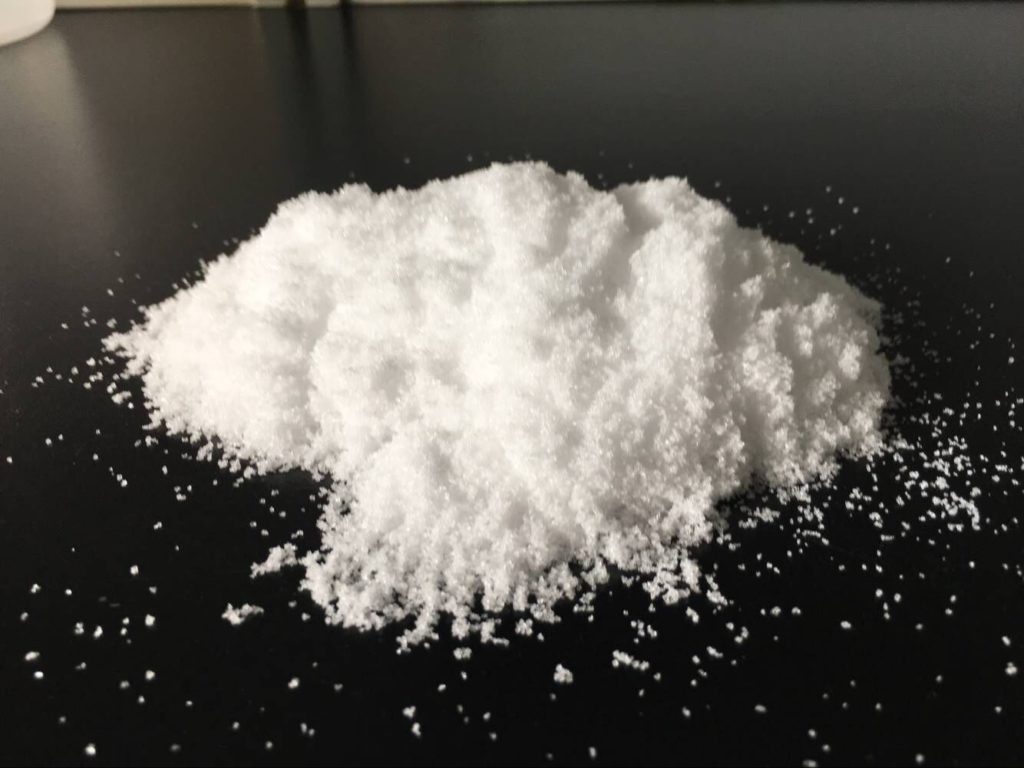

Potassium Chloride, CAS No. 7447-40-7, is a metal halide salt manufactured through chemical synthesis, available as White Crystalline Powder. It is a food supplement for potassium, good for health than Sodium. Potassium chloride is used to prevent or to treat low blood levels of potassium.

We are professional potassium chloride manufacturer in China, the specifications are food grade and pharmaceutical grade. advantages in our potassium chloride manufacturing process as follows:

- Produce potassium chloride with continuous cooling crystallization technology

- Implement close-ended continuous production to avoid the exposure of materials to the surrounding and reduce introduction of external impurities.

- Use corrosion-resistance titanium in all of our main equipment;strictly follow with all requirements for food production during the production process.

- Use continuous cooling crystallization technology to improve the crystallization property of potassium chloride and also the products produced will have high purity and lower impurities content.

- No additional chemical impurity removal reagent is added of used so as to avoid possibility of potential risks.

Use DCS control system for all-process control over the entire production process to ensure stable product quality

Characteristic of DCS control system:

- Offer optimal and the best production environment for potassium chloride crystallization system through precise control of various technical parameters including temperature,liquid level,flow,concentration,vacuum degree and so on. Thereby great improve the stability of product and integrity of crystal structure.

- Further control the impurity content of product in the production process though precise control of flow and the time of washing with purified water during the centrifugal process as well as drying temperature of semi-finished product to lower packing temperature and reduce caking phenomenon in the finished products.

- Use a mature and stable full-automatic packing system to avoid too much exposure to the operating personnel during the packing process and reduce the introduction of external impurities,equip following process with advanced on-line weight recheck balance,metal testing equipment to ensure our products are metal free and 100% qualified net content.