What is Carrageenan E407?

Carrageenan E407 is a family of linear sulfated polysaccharide present in certain species of red seaweed. Carrageenan E407 is made up of repeating units of sulfated D-galactoseand 3,6-anhydro-D-galactose. Carrageenan E407 is a thickener made from seaweed used as gelling agent, stabilizer and thickener.

There are three types of Carrageenan, which differ in their degree of sulfation. Kappa Carrageenan has one sulfate group per disaccharide, Iota Carrageenan has two sulfates and Lambda-carrageenan has three.

Carrageenan E407 is a food thickener that can be used in food as a stabilizer and thickener. Carrageenan is used to improve the texture, taste, and appearance of many foods. Carrageenan can be classified as there types according to the seaweed source: Kappa, iota and lambda carrageenan. Carrageenan can be classified two types based on manufacturing process: Semi-refined and Refined Carrageenan.

- Carrageenan E407 is a vegetarian and vegan alternative to gelatin in some applications or may be used to replace gelatin in confectionery.

- Carrageenan has a synergy effect with other hydrocolloids like konjac gum.

- Carrageenan E number:E407a or E407

- Other names for carrageenan in food, e407 stabilizer, 407 food additive, seaweed extract

Where does Carrageenan E407 comes from?

It comes from seaweed. There are three Types of Carrageenan classified from the seaweed source: Kappa Carrageenan: source from Cottonii seaweed, IOTA CARRAGEENAN: source from Spinosum seaweed, LAMBDA CARRAGEENAN from Gigartina. The largest commercial source of kappa seaweed is in Philippines where the weed is actually farmed rather than wild harvested.

There are two Types of carrageenan classified from extraction process: Refined Carrageenan and Semi Refined Carrageenan. 90% percent of Kappa and Iota Carrageenan is harvested in Philippines. The seaweed for Kappa and Iota are planted in warm water such as in Philippines. LAMBDA CARRAGEENAN can only plant in cold water, most planted in South America.

What is Kappa Carrageenan – Firm & Brittle Gel

- Kappa Carrageenan is sourcing from Cottonii seaweed.

- Use & Application: Kappa has Strongly gelling properties and is mainly used in meat, canned pet food, beer, in some jelly, ice cream and so on. Kappa carrageenan yields a strong Firm and brittle gel than Iota carrageenan. The gel strength is more strong in the presence of potassium ions.

- Solubility: cannot Soluble in water and can soluble at 80⁰C water

- Kappa Carrageenan will be with syneresis when it gels.

- Chemical structure:

What is Iota Carrageenan – Soft & Elastic Gel

- IOTA CARRAGEENAN is sourcing from Spinosum seaweed. Iota carrageenan forms an elastic gel with good freeze thaw and re healing properties.

- It has weak gelling property when compared with Kappa. It is mainly used in soft gel capsules, jelly, ice cream and so on. Kappa and iota can be used together in ice cream and air freshener gels.

- Gel property: The gel made from Iota is Soft and elastic gel.

- Solubility: IOTA CARRAGEENAN is Partially cold soluble in water and can soluble at 80⁰C water

- IOTA CARRAGEENAN can reactive with Calcium ions

- IOTA CARRAGEENAN is free from Syneresis when it gels.

What is Iota Carrageenan – Viscous & Non-gelling Solutions

- Lambda has Non-gelling property is mainly used in chocolate milk. Lambda Carrageenan can be used in food that do not need to heat, like some instant sauce. It is Cold soluble and can react with milk.

- Lambda carrageenan is a highly sulphated type of carrageenan that mainly used for its ability to impart mouth feel and a creamy sensation to dairy products.

Summary of Kappa, Iota, Lambda Carrageenan properties

| Carrageenan Type | Lambda | Iota | Kappa |

| Solubility in Hot (80′ C) water | Soluble | Soluble | Soluble |

| Solubility in Cold(20′ C) water | All salts soluble | Sodium salt soluble | Sodium salt soluble |

| Solubility in Hot (80°C) milk | Soluble | Soluble | Soluble |

| Solubility in Cold(20′ C) milk | Thickens | Insoluble | Insoluble |

| Solubility in Cold milk (TSPP added) | Increased thickening/gel | Thickens or gels | Thickens or gels |

| Solubility in 50% sugar solutions | Soluble | Insoluble | Soluble hot |

| Solubility in 10% salt solutions | Soluble | Soluble | Insoluble |

| Gelation; Effect of cations | Non gelling | Strongest gels with calcium | Strongest gels with potassium |

| Gel texture | Non- gelling | Soft, elastic | Firm, brittle |

| Syneresis | Non gelling | No | Yes |

| Hysteresis

Freeze- thaw stability |

Non gelling

Yes |

5-10’C

Yes |

10-20′ C

No |

| Synergy with locust bean gum | No | No | Yes |

| Synergy with starch | No | Yes | No |

| Shear reversibilitv | Yes | Yes | No |

| Acid stbility | Hydrolysis | Hydrolysis in solution, accelerated by heat; gels are stable | |

| Protein Reactivity | Strong protein interaction in acid | Specific reaction with

Kappa casein |

|

Semi Refined Carrageenan manufacturing process/ carrageenan extraction process

- Semi Refined Carrageenan: Cleaned and washed seaweed → Cooking → Decolorization → Dry → Mill → Packaging

- Refined Carrageenan: Cleaned and washed seaweed→ Extraction (move cell wall cellulose)→ Filtration/Gelation (using filter aid)→ dry→ Mill→ Packaging

- Refined carrageenan is mainly made from solution by alcohol precipitation or potassium gelation.

- Semi-refined carrageenan is washed and alkali treated seaweed. Semi-refined carrageenan does not move cell wall cellulose and it is not extracted out of the seaweed. The color of Refined carrageenan is clean than Semi-refined carrageenan.

Semi refined carrageenan and refined carrageenan

- The essential difference in the refining process is that the carrageenan is first dissolved and filtered to remove cell wall cellulose.

- Color: Refined Carrageenan is more clean than Semi Refined Carrageenan

- Gel strength: the Gel strength of refined carrageenan is more higher than Semi refined carrageenan

- Viscosity:

Carrageenan E407 Benefits

Carrageenan skin benefits

You may find cosmetic products with Carrageenan such as in toothpaste, facial moisturizer, shampoo/conditioner, shaving cream, foundation, sunscreen and cleanser. Carrageenan Works as a thickening agent, binder and hair conditioning agent. It has excellent water binding properties, as well as the ability to form gels at room temperature. They provide a wide array of textures and can stabilize a variety of formulations such as emulsion, foams and suspensions.

Carrageenan E407 Application

Based on the properties of carrageenan E407, it is commonly used as a thickener, gelling agent, suspending agent, emulsifier, stabilizer, etc. in the food like meat, frozen dessert, chocolate milk, almond milk, coconut milk, soy milk, beer, sauces, pet foods, coffee, hot cereal beverages, confectionery, ice creams, yogurts, cottage cheese, whipping creams, fruit jellies, soft drinks, ham, salad dressings, infant formulas, dried pasta products, fish products, vegetarian hot dogs. It can be also used in medicines, laxatives, air freshener Gel, toothpastes, shampoos and so on.

Carrageenan In meat

- Injected and/or Tumbled Meat: meat and solution is added to a rotating chamber with baffles, subjecting the meat pieces to a gentle beating process.

- Emulsified Meat: brine solution containing water and salt is distributed to whole muscle meat product.

- Canned Meat

Carrageenan Function in meat

- Stabilizes fat-protein emulsion preventing separation of the fractions which in effect gives a more homogenous, better cut

- Improves texture, slice ability and mouth feel

- Improves water

- Improves holding capacity: weight yield

- Stabilise water-fat-protein emulsion

- Carrageenans disperse well in water without increasing density which makes injecting easier – low density is retained until heat treatment

- Improve freeze and thaw stability

If you need the meat soft, you can use iota carrageenan, if you need hard meat, you can use kappa carrageenan.

If meat without Carrageenan, it will be poor slice ability, high purge, not freeze-thaw stable and Lower yield.

If with Carrageenan, meat will be with better slice ability, reduced purge, Freeze-thaw stable and Increased yield.

How to evaluate Carrageenan quality in meat?

Physical Analysis

- Color

- Odor/Taste

- Particle Size

- Dispersion Property

- Slice ability

Chemical Analysis

- Carrageenan Content

- Chloride Content

- Presence of Other Hydrocolloid Gums

Gel evaluation

Gel Strength and Texture

- Water Gel Strength

- Potassium Gel Strength

- Brine Gel Strength

- Calcium Gel Strength

- Meat Gel Strength

Carrageenan In Jelly

Carrageenan function in jelly

- Allows quick gelation

- Controls syneresis

- Provides excellent flavor release

- Provides stability at room temperature

- Offers thermo reversability

- Gives desired jelly opacity/transparancy

As a good gelling agent, Carrageenan can replace agar agar, gelatin and pectin. The jelly which made of agar lacks elasticity and the price is relatively high. The disadvantage of gelatin made jelly is that the freezing and melting point is low, and both the preparation and the storage require low-temperature refrigeration; the disadvantage of using pectin made jelly is that it need to add high-soluble sugar and adjust the proper pH to form the gel. Carrageenan does not have these disadvantages. Jelly made from carrageenan is elastic and not water-repellent. Therefore, it becomes a gel commonly used for jelly.

It should pay attention to the following points when Carrageenan used in jelly:

Since carrageenan solubility is relatively low, so it is necessary to carry out heat preservation. If the holding time of heat preservation is not enough, dissolution will be not complete, and the taste of the jelly will be not good, serious will cause the jelly is tender and not forming; but at the same time the holding time is too long, carrageenan and alkali or sodium citrate added Buffers are prone to deacetylation, resulting in an “egg soup” phenomenon. The jelly may not be formed. Therefore, it is recommended that you do not keep warm after boiling in the summer, keep warm for 10 minutes after boiling in winter, and fall between the two in spring and autumn.

As Carrageenan is not acid-resistant, the lower the acid temperature is, the better it is. Generally, before the jelly filling at 70°C-80°C or according to the actual process conditions, the higher the temperature, the more easily the carrageenan will be damaged, which will affect the taste. citric acid is suggested to add after dissolved in water to avoid causing local acidity; the pH is generally adjusted to not less than 4. If a more acidic taste is desired, adding other colloidal aids can be used; pasteurization will also affect the taste and need to be adjusted according to actual conditions.

Jelly Evaluation

- pH Determination

- Viscosity Test

- Gel Strength and Texture Analysis

- Clarity of Gel

- Determination of Syneresis

Carrageenan in Gummy candy

Gummy candy (also known as chewy or jelly candy) is a type of chewable product containing a high sugar content. It is commercially produced as a confectionery that comes in varying shapes, sizes and flavors.

The use of carrageenan in candy popular in China. Carrageenan made candy has a strong fruit aroma, a moderate sweetness, and a refreshing non-stick tooth. It is also more transparent than agar agar and has a lower price than agar agar. It is added to hard and soft candies in general. It Can make the product taste smooth, more flexible, low viscosity, increased stability.

Carrageenan in ice cream

In the production of ice cream and ice cream, carrageenan can evenly distribute fat and other solid components, prevent the separation of milk components and increase ice crystals during manufacture and storage. It can make ice cream and ice cream delicate, smooth and delicious. In the production of ice cream, carrageenan can react with cations in milk to produce unique gelling properties that increase the formability and resistance to melting of ice cream, increase the stability of ice cream during temperature fluctuations, and do not easily melt when placed.

In the production of ice cream, carrageenan is not suitable as the main stabilizer, but it can be used as a good stabilizer to prevent whey separation at very low concentrations. As carrageenan increases the viscosity of the system, it does not contain enough glue to stabilize the system. Locust bean gum, guar gum, and carboxymethyl cellulose, either alone or in combination, are preferred primary stabilizers, however they have the same disadvantage that they cause whey separation in the ice cream mixture. Therefore, the use of carrageenan in ice cream can inhibit the occurrence of this phenomenon.

Carrageenan used in ice cream should pay attention to: First, you can add a small amount of starch filling, there are more than a powder texture, poor taste; Second, the amount of carrageenan is less, mostly used in the freezing process after aging.

Carrageenan in Yogurt

As far as we know, carrageenan can be used in yogurt due to the very low PH in yogurt. As a carrageenan manufacturer and supplier for years, we have carrageenan type for yogurt application.

If the flavor is needed in final products, it should be added after cool down, as Kappa and Iota need to heat to 80 to make it dissolved, that will make some flavor volatilize or decompose.

Carrageenan powder is stable, the shelf life can be long as it is difficult to degrade. It is also stable in neutral and alkaline solutions, and will not hydrolyze even when heated, but carrageenan is prone to acid hydrolysis in acidic solutions (especially pH ≤ 4.0) and the gel strength and viscosity will decrease. It is worth noting that under neutral conditions, if carrageenan is heated at high temperatures for a long time, it will also hydrolyze, leading to a decreasing in gel strength. All types of carrageenan are soluble in hot water and hot milk. Soluble in hot water to form a viscous transparent or slightly milky flowable solution. Carrageenan can only swell in water and cannot dissolve in cold water (only Lambda can dissolve).

Summary of Kappa, Iota, Lambda Carrageenan use in food

| Application | Function | Carrageenan type | Use level (%) |

| Dessert gels | Gelation | Kappa/iota/kappa + iota | 0.5-1.0 |

| Non-dairy pudding | Emulsion stabilization | Kappa | 0.1-0.3 |

| Syrups | Suspension, bodying | Kappa | 0.3-0.5 |

| BBQ and pizza sauces | Bodying | Kappa | 0.2-0.5 |

| Whipped toppings | Emulsion stabilization | Kappa | 0.1-0.3 |

| Imitation coffee creams | Emulsion stabilization | Lambda | 0.1-0.2 |

| Pet foods | Gelation, fat stabilization | Kappa | 0.5-1.0 |

| Salad dressing

Beer and wine |

Suspension

Clarify and reduce chill haze |

Iota

Kappa |

0.3 |

| Cold-prepared custards | Thickening, gelation | Kappa, Iota | 0.2-0.3 |

| Puddings | Reduce starch | Kappa | 0.1-0.2 |

| Ready to eat desserts | Syneresis control | Kappa +Iota | 0.1-0.2 |

| Whipped cream | Stabilize overrun | Lambda | 0.0 的 .15 |

| Aerosol cream | Stabilize emulsion/overrun | Kappa | 0 . 02-0 .05 |

| Yogurt | Fruit suspension, mouthfeel | Kappa2 | 0.2-0.5 |

| Chocolate milk | Suspension, mouthfeel | Kappa2, Lambda | 0.015-0.030 |

| Soy milk

Evaporated milk |

Suspension. mouthfeel

Prevent whey separation |

Iota, Kappa

Kappa |

0.03-0.10

0.005-0.015 |

| Processed cheese | Improved grating/slicing | Kappa | 0.3-2.0 |

| Cream cheese | Gelation, moisture binding | Kappa | 0.3-0.5 |

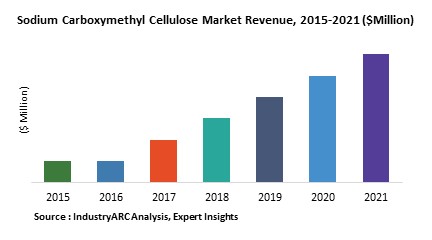

Carrageenan E407 market

Carrageenan E407 is a major ingredient in the food and is used for its gelling, thickening and stabilizing properties. It has wide applications in both dairy and meat products.

Carrageenan E407 market is increasing. Carrageenan use in meat takes around 40-50% of carrageenan consumption in global market. The major driver of the carrageenan market is the rising demand for processed foods that need health ingredients. Within the processed food ingredients, the rising demand for nature or plant extract ingredients is driving the use for carrageenan. Other very important factor for the market growth is the large number of functional and health benefits of carrageenan. It acts as a stabilizer, thicker, texturing and gelling agent.

Kappa and Iota Seaweed harvest is not good in during October to November, as there will be strong typhoon in Philippines, so the tight supply of seaweed will lead to the price of raw materials going up, which will make carrageenan E407 price increase accordingly.

Carrageenan E407 manufacturers

China is the big Carrageenan E407 manufacturers and export country in the world.

There are several Carrageenan E407 manufacturers in China and abroad, as you know, the price of China suppliers can be better than abroad manufacturers. We have worked with China top manufacturer for years, we would like to recommend this Carrageenan E407 brand to you if you would like to save your purchasing cost with the same quality compared with abroad manufacturers.Carrageenan E407 Samples are available if you need it for further test after accept the price.

Carrageenan E407 price

As you know, there are many types of Carrageenan E407 in the market, the price is based on different type. Now the price of Carrageenan E407 is around USD/kg from China manufacturers and suppliers.

Where to buy Carrageenan E407

All the products listed in our website are from the manufacturers we have worked together for many years. The professional working experience backup our confidence to their quality. We can supply Carrageenan E407 for many Specifications and we can be your suppliers in China.

By using the appropriate carrageenan types in your food, the formulator can create textures ranging from free-flowing liquids to solid gels. In addition to offering standard types, we works in conjunction with customers to develop new carrageenan types for specific applications.

We’re committed to the quality and safety of our ingredients. We know that our customers expect us to use only the highest quality and healthiest ingredients available, and we do everything we can to satisfy those expectations. We feel confident in our choice to choose top carrageenan manufacturer brand.

If you have any other questions, please email us through: info@foodsweeteners.com

Carrageenan E407 Side effects

Carrageenan controversy

Although Carrageenan is approved safe to use by FDA, some scientists have presented evidence that carrageenan is highly inflammatory and toxic to the digestive tract, and claim that it may be responsible for colitis, IBS, rheumatoid arthritis, and even colon cancer.

Source: https://www.scientificamerican.com/article/the-carrageenan-controversy/

There are two forms of carrageenan: food grade and degraded. Food grade carrageenan has been used for hundreds of years and has been extensively reviewed and approved for use in foods. Degraded carrageenan was found to be harmful, but is not used in foods, as it does not provide any thickening properties. Even though degraded carrageenan and food-grade carrageenan are different, the harmful effects of carrageenan in its degraded form have been mistakenly associated with food-grade carrageenan.

FDA states that “While no evidence in the available information on undegraded carrageenan demonstrates a hazard to the public when it is used at levels that are now current and in the manner now practiced, uncertainties exist requiring that additional studies should be conducted.”

Source: http://wayback.archive-it.org/7993/20171031071338/https://www.fda.gov/Food/IngredientsPackagingLabeling/GRAS/SCOGS/ucm261246.htm

Carrageenan is safe for pregnancy?

Carrageenan, in amounts typically found in foods, is safe to use during pregnancy and breastfeeding, but not enough studies have been done to evaluate its safety in larger amounts.

Carrageenan health risks

Carrageenan health risks may as follows:

- inflammation

- bloating

- irritable bowel syndrome

- glucose intolerance

- colon cancer

- food allergies

How much Carrageenan is safe?

Food grade carrageenan has been independently evaluated by the Joint FAO*/WHO* Expert Committee on Food Additives (JECFA), an international panel of expert toxicologists who review data and develop recommendations about food ingredients. JECFA determined that food grade carrageenan was a safe food additive with no limits on its use in food.

Carrageenan E407 FAQ

Agar and carrageenan

Carrageenan nutrition facts

Agar agar vs carrageenan

Is carrageenan an emulsifier

Carrageenan vs gelatin

Carrageenan vs xanthan gum

To be continued…