What is sodium carboxymethylcellulose?

Sodium Carboxymethylcellulose is the sodium salt of Carboxymethyl cellulose, also called Sodium CMC (Sodium CarboxymethylCellulose) or CMC. Carboxymethylcellulose is a representative cellulose ethers, its sodium salt used widely in food industry, CMC belongs to anionic polymer electrolyte, besides Sodium CMC, it has other salts, such as ammonium and aluminum CMC salts.

Sodium Carboxymethylcellulose E466 can be used as a thickener in food and has the functions of thickening, suspending, emulsifying, stabilizing and etc. Sodium CMC can replace the use of guar gum E412, gelatin, Agar Agar E406, sodium alginate E401 and pectin E440. It is widely used in food industry, such as frozen food, solid drink, fruit juice, jam, lactic acid drinks, condiment, biscuit, instant noodles, bakery products, meat products, etc.

Other information about Sodium Carboxymethylcellulose:

CAS Number: 9004-32-4

HS code: 391231

E Number: E466

Sodium Carboxymethylcellulose Properties

Appearance

Sodium CMC is odorless, tasteless, non-toxic white powder or micro-yellow fibrous in pure state.

Solubility

Sodium CMC is easy to absorb moisture, it dissolves easily in cold or hot water as colloidal solution, it can’t dissolve in many organic solvents such as methanol, ethanol, acetone, chloroform, benzene and so on.

CarboxymethylCellulose CMC is not easy to dissolve in water. It is water-absorbent and has very high water retention, and therefore clumps easily. To prevent this, add CMC slowly in small portions, allowing to dissolve completely between each addition.

Degree of Substitution (DS) of Carboxymethylcellulose is an important factor affects its water solubility property, the viscosity property can also affect its water solubility. Sodium CMC is usually alkali when viscosity value between 25mPa.s-50000mPa.s. Degree of Substitution (DS) is about 0.3. Sodium CMC is water-soluble when its Degree of Substitution (DS) is more than 0.4. With the increasing of Degree of Substitution (DS), the transparency of the Sodium CMC water solution becomes much better. Like other macromolecule dielectric, when Sodium CMC dissolving, the first phenomenon is expansion, and then dissolve gradually. In preparation solution, the particles should be uniform wetting, then the Sodium CMC can be dissolved quickly. Otherwise, Sodium CMC are expansion in water solution, the particles form a strong involucres or plastic coating, so that the particles scattered difficulty resulting dissolution difficulty.

Viscosity

Sodium CMC viscosity is the specific performance of Polymerization Degree of the cellulose, it depends on the average degree of materials cellulose, and the degradation of polymerization degree in the course of basification and etherification reaction, including the reaction uniformity. With the increase of its concentration, Sodium CMC viscosity will go up and the increase trend was similar to a straight line. Viscosity have relative with the polymerization degree of the cellulose and its distribution, but also have relative with the solution concentration, pH value, temperature, velocity gradient, Degree of Substitution (DS) and so on.

Different Viscosity with different uses in food. And there are many Sodium CMC grade in the market according to different purity, Degree of Substitution and Viscosity. Our Sodium CMC grades as follows:

| Type | Viscosity | Uses Area |

| Type 6 | Low Viscosity

(2% 25-400) |

Cold products, quick-frozen food, solid beverage, fruit juice, jam, sauce, soup, biscuits, instant noodles, baking goods and meat products, etc. |

| Medium Viscosity

(2% 400-2000) |

||

| High Viscosity

(1% 200-9000) |

||

| Ultra High Viscosity

(1% 9000-15000) |

Food fields where there should be ultra-high requirement on viscosity | |

| Type 9 | Low Viscosity

(2% 25-400) |

Lactic acid beverage, yogurt products |

| Medium Viscosity

(2% 400-2000) |

||

| High Viscosity

(1% 200-7000) |

Sodium Carboxymethylcellulose Market

Market demand

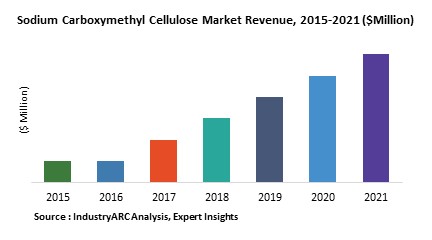

The global sodium carboxymethyl cellulose market is estimated to grow at a CAGR of 2.7% during the forecast period and will reach $2.26 billion by 2021. The major driving forces of this market are: consumption of sodium carboxymethyl cellulose is anticipated to witness growth in Asia-Pacific region driven by food, beverages and pharmaceutical industries and increasing demand for low fat foods along with significant utilization of Sodium CMC as a stabilizer and texture enhancer in bakery products.

Manufacturers

There are several Sodium Carboxymethylcellulose manufacturers in China. Due to the environment protection problem, the production is limited in these years.

Price

Currently the price is stable.

Sodium Carboxymethylcellulose side effects

It is a food thickener generally consider safe. Although Sodium Carboxymethylcellulose is generally deemed a safe and acceptable foodthickener, there’s still the potential that there are as yet unknown risks.

Carboxymethyl cellulose is very soluble, and can be fermented in the large intestine. Large concentrations may cause intestinal problems, such as bloating, constipation and diarrhoea.

Dietary restrictions:

Sodium Carboxymethylcellulose can be consumed by all religious groups, vegans and vegetarians.